架空光缆是什么意思 , 架空光缆用什么型号的 GYTC8A , 架空光缆型号是啥

8字形光缆

产品描述 Description

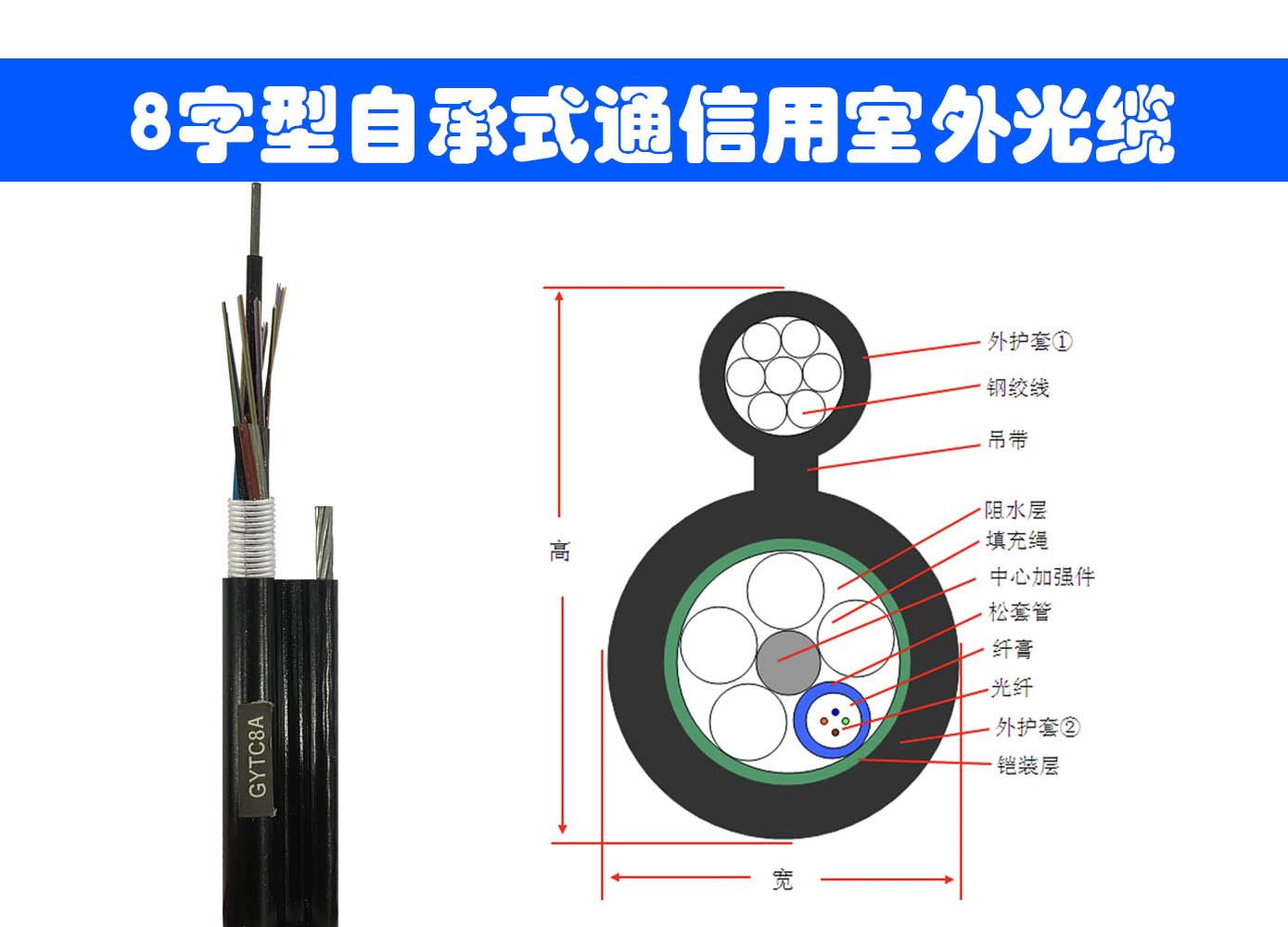

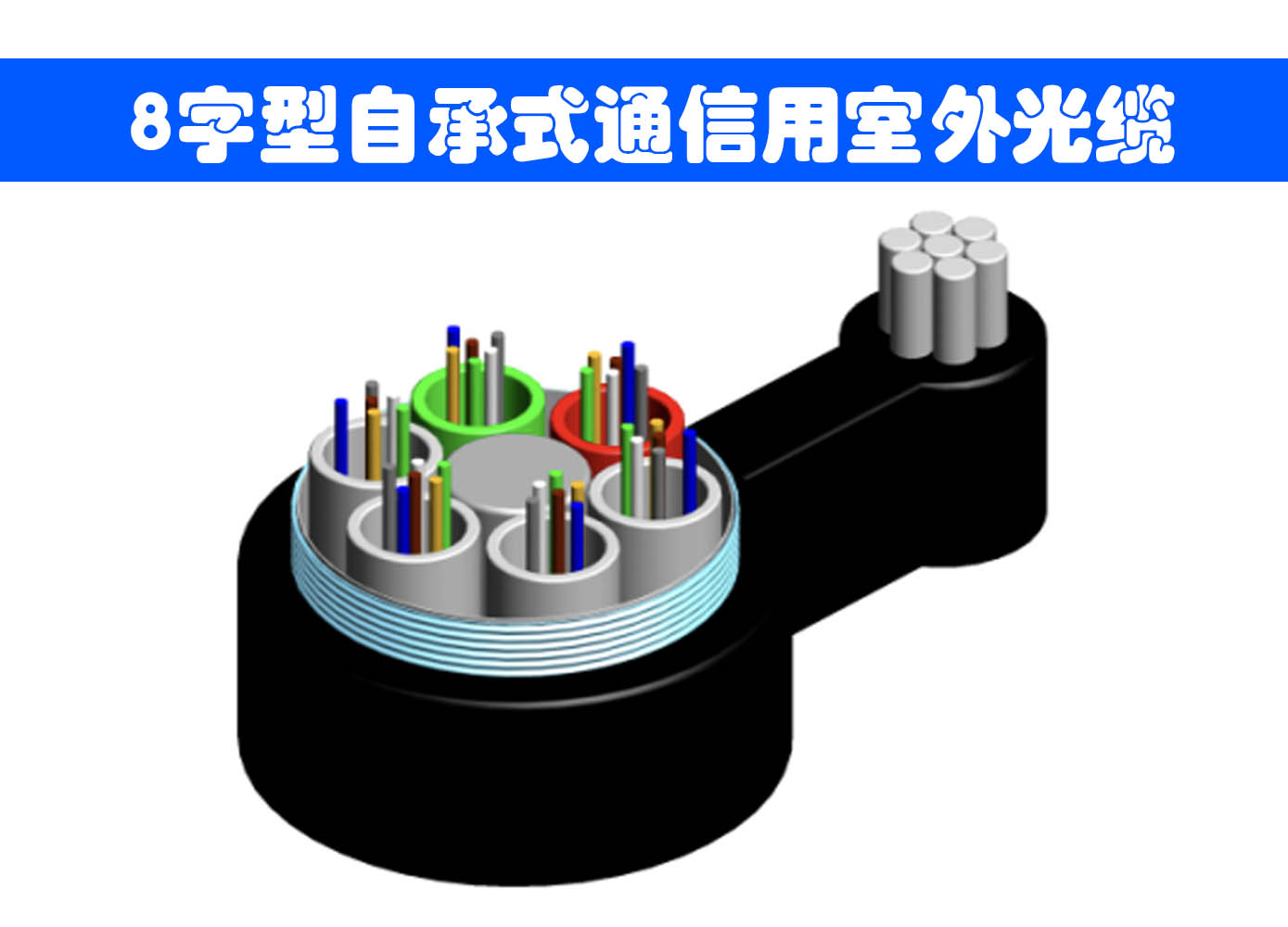

GYTC8A光缆的结构是将250µm光纤套入高模量材料制成的松套管中,松套管内填充防水化合物。缆芯的中心是一根金属加强芯,松套管(和填充绳 )围绕中心加强芯绞合成紧凑和圆形的缆芯。缆芯用一层涂塑铝带(APL)纵包后,和钢丝绞线集成到一个8字型的聚乙烯护套内。

The fibers, 250μm , are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire locates in the center of core as a metallic strength member. The tubes (and fillers) are stranded around the strength member into a compact and circular cable core. After an Aluminum Polyethylene Laminate (APL) moisture barrier is applied around the cable core, this part of cable accompanied with the stranded wires as the supporting part are completed with a polyethylene (PE) sheath to be figure 8 structure.

8字缆 光缆

产品特点 Characteristics

钢丝绞线具有极高的抗拉强度,便于自承式架空敷设降低安装成本。

High tensile strength of stranded wires meet the requirement of self-supporting and reduce the installation cost.

光缆具有很好的机械性能和温度特性

Good mechanical and temperature performance

松套管材料本身具有良好的耐水解性能和较高的强度

High strength loose tube that is hydrolysis resistant

管内充以特种油膏,对光纤进行了关键性保护

Special tube filling compound ensure a critical protection of fiber

采用下列措施来确保光缆的防水性能

The following measures are taken to ensure the cable watertight

单根钢丝中心加强芯

Single steel wire as central strength member

松套管内填充特种防水化合物

Special tube filling compound ensure a critical protection of fiber

完全缆芯填充

Fully filled in the cable

涂塑铝带(APL)防潮层

APL layer

gytc8a参数表

| gytc8a参数表 | |||

| 光缆芯数 | 光缆结构 | 光缆松套管内

最大光纤芯数 |

光缆重量

(kg/km) |

| 2-30 | 1+5 | 6 | 135 |

| 32-60 | 1+5 | 12 | 147 |

| 74-96 | 1+6 | 12 | 172 |

| 62-72 | 1+8 | 12 | 198 |

| 98-120 | 1+10 | 12 | 220 |

| 122-144 | 1+12 | 12 | 246 |

| 146-216 | 1+6+12 | 12 | 271 |

| 218-300 | 1+9+15 | 12 | 311 |

| 允许拉力(N)短期 | ≥1500N | ||

| 允许拉力(N)长期 | ≥600N | ||

| 允许压扁力-短期 | ≥1000(N/100mm) | ||

| 允许压扁力-长期 | ≥300(N/100mm) | ||

1、典型值可根据实际情况做相应调整;

2、可根据客户要求进行相应产品的设计;

产品标准 Standards

GYTC8A光缆符合YD/T 1155-2001和IEC 60794-1标准

GYTC8A cable complies with Standard YD/T 1155-2011 as well as IEC 60794-1.

光缆环境性能

| 试验项目 | 试验方法 |

| 温度循环试验 | a.温度台阶:+20℃、-40℃、+70℃、+20℃;

b.保持时间:单护套光缆每一台阶12小时,双护套光缆每一台阶24小时,循环次数:2个循环; |

| 渗水试验 | 成品后光缆渗水性能应符合IEC60794-1-F5B规定,在光缆全截面上进行,满足1m水柱,1m光缆,8小时不渗水。 |

| 光缆外护套

绝缘电阻 |

光缆外护套绝缘电阻(外护层内铠装层与大地间),在光缆浸水24小时后测试,不小于2000MΩ•km(直流500伏测试)。 |

| 介电强度 | 外护套内铠装层与大地间:在光缆浸水24小时后测试,不小于直流15千伏2分钟。对双护套光缆,要求外护套内铠装与金属加强芯间:不小于直流20千伏5秒钟,符合GB/T 1408.1-2006规定。 |

| 滴流试验 | 在温度为70℃(24h)的环境条件下,光缆应无填充复合物和涂覆复合物等滴出。 |